Melting two metal surfaces to get them to merge into one is what welding essentially is. This doesn't happen easily though as extremely high temperatures need to be generated in order to melt metal be it a workpiece or a rod supplied to the welder.

For this, high amp current is drawn at a fast rate and thus the welding machine is able to quickly and efficiently bring any metal to its melting point. This then acts much like a glue that quickly solidifies and makes for the strongest joints and the longest-lasting metal fabrication projects. But there is not just one way to weld metal pieces and therefore there are different types of equipment.

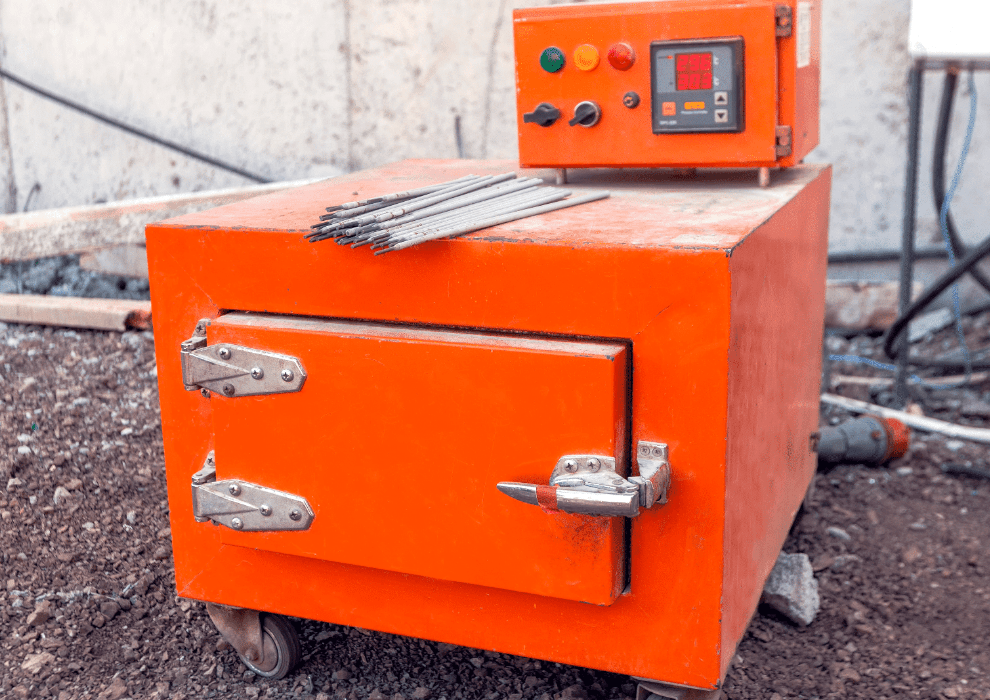

Welding Rod Ovens

What Are They?

One piece of welding equipment that's not always needed but can make a big difference no matter the welding process is an electrode oven. Also known as rod ovens, welding electrode ovens are used to rebake or recondition electrodes contaminated with hydrogen. An electrode oven can also be used to store electrodes that aren't contaminated and keep them safe from exposure to moisture.

Types

Depending on what you want to do with your electrodes, you can have either a holding or a rebake welding rod oven. Also known as storage rod ovens, holding ovens are used to keep electrodes in good condition and safe from contamination. In this case, you need to set the oven to a specific temperature in order for the rods to stay usable. Rebake ovens, are as you'd expect, used to make contaminated electrodes usable again which makes them more expensive as they can reach higher temperatures.

What to Look for in a Welding Rod Oven

Control

There are two factors that a welding oven needs to have control of and those are, of course, temperature as well as humidity. A rod oven should be able to keep the exact temperature for the period in which a certain type of electrode is inside. Different electrodes require different temperatures for different use case scenarios. The way an electrode is reconditioned or kept ready for the welding machine is also affected by the humidity inside the oven which is why one that controls it is preferred. Any moisture in any electrode can make it so that you get welding defects later on.

Durability

A welder's workspace is a harsh environment even for equipment made for welding purposes and the same goes for welding ovens. They should be made of strong and weighty materials that will make them not only survive in demanding conditions but also last a long time without any issues. This is usually the case with rebake ovens as they're made to generate and withstand higher temperatures.

Size

The capabilities of an electrode oven also depend on its size. A larger oven is able to hold more electrodes and therefore it's usually made of higher quality materials than a smaller one. The heavier the oven typically, the longer lasting it is but that's not always the case. As long as the oven you go for can hold the number of electrodes you need at a time, you most likely have a fitting product.

Portability

If you want to have a welding rod oven by your side while welding then a more portable one is what you should look for. Welding ovens can be so small that you can lug them around with you but know that these aren't that capable in terms of the number of electrodes they can store and the temperatures they can maintain.

Using a Welding Rod Oven

1. Part of having a constant supply of welding rods in good condition involves using a welding oven regularly. This starts by checking the rods and then placing them in the oven unless they are bent, rusted, corroded or damaged.

2. Before you do that though, the oven needs to be preheated in order for the electrodes to be prepared for the welder in the most efficient way possible. Just make sure that you set the oven to the correct temperature according to manufacturer-stated values for the electrode at hand.

3. Once the set temperature has been reached, place the electrodes in the oven and close the lid properly so that there's no heat escaping. Also, ensure the fan is on so that no moisture gets trapped while the electrodes are in the oven.

4. Pay attention to both the humidity and temperature levels, to keep the electrodes exposed to the correct temperature levels and with no moisture in them for the right amount of time.

5. Once the electrodes have been exposed to a certain temperature for long enough, just open the lid and take the electrodes out. Before you use them let the rods sit for a couple of minutes at room temperature.

Welding Ovens vs Quivers

The main difference between welding electrode ovens and quivers is that the former are made to heat up the electrodes to keep them usable while the latter are not. Simply put quivers prevent moisture build-up and that's it they don't generate heat.